From Audit to Action

Audits and surveys are one of the richest streams of operational intelligence a company will ever collect. Yet in most organizations, that intelligence dies in a spreadsheet or a filing cabinet. In highly regulated industries — pharma, chemicals, heavy manufacturing — that’s not just inefficient. It’s dangerous. Blind spots cost money, reputation and sometimes lives.

The Real Risk Isn’t Compliance — It’s Latency

Paper forms, email surveys and disconnected databases create high latency. By the time data is compiled, the conditions it describes have already changed. That’s how contamination sneaks into a batch, an ergonomic injury festers into a lost-time case, or a small environmental release turns into a major fine. The problem isn’t a lack of data. It’s a lack of timely, trustworthy data in a form leaders can use

Digital EHS Flips the Script

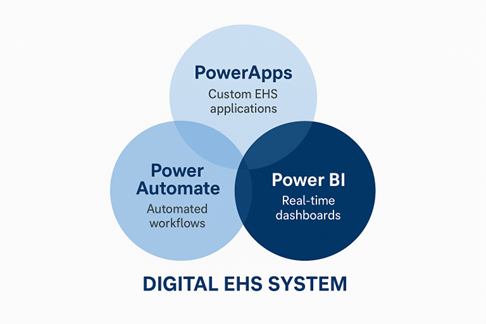

Digital Environmental, Health and Safety (EHS) systems built on Microsoft Power Platform turn audits from static paperwork into live, actionable data:

Smart capture (Power Apps): mobile apps with built-in validation, required fields, GPS and timestamps replace clipboards and spreadsheets.

Automated workflows (Power Automate): data is instantly moved to the right people; threshold breaches trigger alerts; incidents are routed automatically to reviewers; audit packets assemble themselves overnight instead of over weeks.

Live dashboards (Power BI): executives see compliance status, risk indicators and trends in real time instead of waiting for quarterly reports.

It’s the difference between snapshots and live video. You don’t just document; you monitor and act.

Proof From the Field

A multinational pharmaceutical company replaced its paper-based audits and health surveys with a Power Platform solution:

Pre-audit prep dropped from 80+ hours per site to 12.

Data entry errors fell from 15–20% to 3%.

Response time to flagged issues shrank from 14 days to three.

Cross-site compliance standardisation jumped from under 50% to over 90%.

Freed from administrative drudgery, safety professionals focused on prevention and training. Regulatory inspections that once meant weeks of frantic preparation became an exercise in pulling up a dashboard.

The Business Case: Decision Advantage

OSHA fines average more than $15,000 per violation; environmental penalties can exceed $100,000 per incident. Insurance carriers now offer discounts to firms with real-time EHS management. Workers’ compensation costs drop when incidents are prevented rather than recorded.

Most companies that go digital recover implementation costs within 12–18 months through:

60–80% reduction in manual hours

Weeks shaved off audit preparation

Dramatic reductions in training administration and incident closure times

Lower consultant and legal fees during regulatory investigations

But the real payoff is strategic. In customer audits and contract bids, digital EHS capabilities are becoming a differentiator. They signal maturity, control and transparency — qualities that matter as much to investors and partners as they do to regulators.

From Ritual to Engine

The old model of scheduled audits and paper trails was built for a slower era. In an environment of 24/7 operations, instantaneous media scrutiny and rapidly shifting standards, it’s obsolete. Digital EHS enables a different posture: you’re not waiting for the next inspection to find out what’s wrong; you’re already seeing and fixing it.

That’s what “From Audit to Action” really means: treating compliance data as an operational asset, not a burden. The technology exists. The leadership mindset is what’s scarce.

How to Start

Pick one high-pain process — employee health surveys or routine audits — and digitize that first

Design for the frontline. If the app isn’t easier than paper, adoption will falter

Automate the obvious. Use workflows to eliminate copy-paste and email chains

Show the dashboards. When managers see live data, they’ll demand more

Each step builds the foundation for a full EHS platform without a big-bang rollout

Digital EHS systems built on platforms like Microsoft Power Platform let leaders move from reactive compliance to proactive risk management — and gain a genuine decision advantage.