Data Mining Decides What to Automate Automation Decides How Fast You Scale

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

Automation doesn’t fail loudly.

It fails quietly.

Bots keep running. Dashboards stay green. And slowly, the organization scales the wrong work.

Almost every failed automation program shares the same root cause:

automation was designed before understanding the data.

Let’s break this down.

1. Why Automation Should Start With Data Mining

Most automation initiatives begin with opinions.

This process feels slow.

That step looks manual.

This team complains the loudest.

Data mining replaces those assumptions with evidence. It shows:

What actually repeats

Where work breaks

Where time and effort really go

Only then does automation make sense.

Don’t automate opinions. Automate patterns.

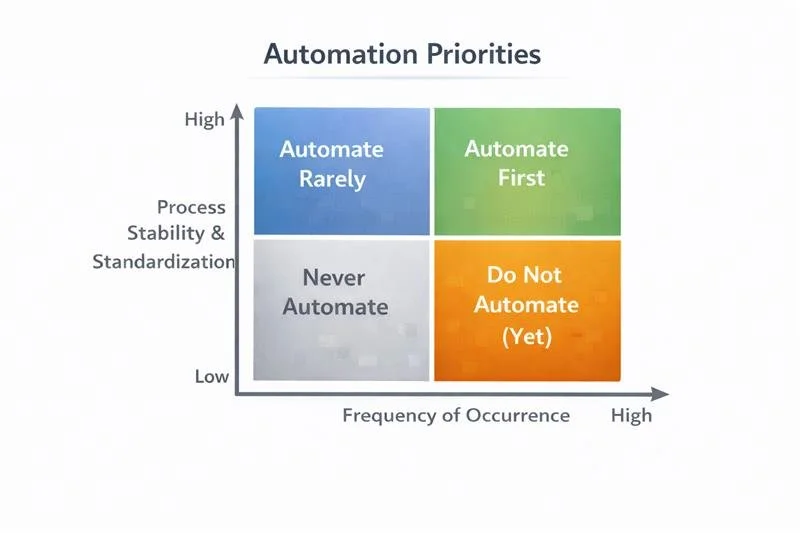

2. Visible Work Isn’t Always Repeatable Work

Some tasks look important because they’re visible. Emails. Approvals. Escalations.

But visibility doesn’t mean stability.

Data mining highlights work that is:

Frequent

Predictable

Consistent over time

Those are the real automation candidates.

Frequency beats visibility when choosing automation.

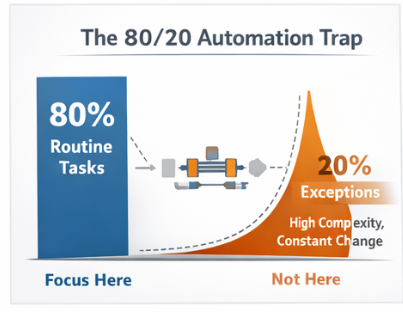

3. Automating Exceptions Is the Fastest Way to Fail

Teams often start with the most painful cases.

Edge scenarios. Complex exceptions. One-off fixes.

Data mining usually reveals something uncomfortable:

those cases are rare, inconsistent, and constantly changing.

Automate them, and your bot becomes a full-time firefighter.

Automate the boring 80%, not the noisy 20%.

4. Data Mining Exposes Where Humans Are Propping Up Bad Processes

Manual workarounds don’t exist by accident.

People bypass steps because:

Systems are slow

Rules don’t match reality

Processes break under pressure

Mining the data shows where humans are compensating just to keep work moving.

Automating those workarounds without fixing the root cause only locks the problem in.

Automation should fix the process, not replace human hacks.

5. Automation Without Mining Creates Blind Spots

Without data mining, teams don’t know:

True volumes

Variation across cases

Actual failure rates

Automation then scales assumptions instead of reality.

And speed without visibility is dangerous.

Speed without visibility creates risk.

6. Mining Shows Effort. Automation Removes It.

Cost is easy to see. Effort is not.

Data mining quantifies:

Touchpoints

Rework loops

Waiting time

Handovers

Automation should target effort first. That’s where real value lives.

If you can’t measure effort, you’ll automate the wrong steps.

7. Why So Many Bots Break After Go-Live

Bots fail when reality changes.

New rules. New volumes. New behaviors.

Data mining helps design automation around how work actually happens, not how it’s supposed to happen on paper.

That difference decides whether an automation survives six months or six weeks.

Automations that reflect reality survive longer.

8. Mining Reduces Automation Maintenance

When patterns are clear, automation logic stays simple.

Fewer exceptions.

Less branching logic.

Lower maintenance cost.

Complex automation is often a symptom of poor inputs.

Better inputs reduce long-term automation cost.

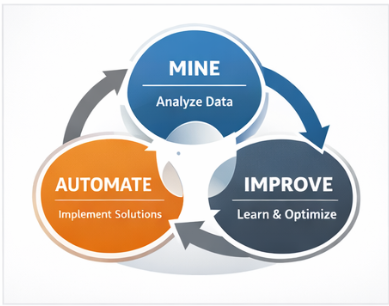

9. Mining and Automation Are a Loop, Not a Project

The real flow looks like this:

Mine → automate → mine again.

Automation changes behavior.

Behavior changes data.

Data reveals new opportunities.

That loop is where continuous improvement actually happens.

Automation is not the end state. Learning is.

10. What “Good” Actually Looks Like

Strong automation programs follow a simple sequence:

Data mining identifies repeatable patterns

Automation targets stable steps

Metrics track impact

Teams review, learn, and refine