Process Mining: The Underutilized Capability Enterprises Should Revisit

In recent years, process mining was widely regarded as the next major advancement in enterprise transformation. Although the momentum slowed once AI dominated the industry narrative, the relevance of process mining has only grown. Many organizations are now realizing that predictive intelligence, automation and AI initiatives cannot succeed without an accurate understanding of how their internal processes actually function.

Process mining provides that clarity. It replaces assumptions with evidence and transforms system logs into a precise representation of real operational workflows.

What Is Process Mining?

Enterprise systems such as ERP, CRM, MES, and service platforms record every activity that happens inside them — when a task is created, approved, updated, delayed, closed, or moved. Each record includes a timestamp, the user or system involved, and any related transaction details.

Process mining brings all of these digital records together and rebuilds the real operational workflow across the organization.

This offers a factual view of operations, highlighting:

actual process flows versus documented flows

bottlenecks and delays

rework loops

compliance deviations

manual workarounds

inefficiencies across handoffs and approvals

In essence, it delivers a data-driven representation of end-to-end operations—something traditional workshops or audits cannot achieve with the same level of accuracy.

A Practical Example

A manufacturing organization estimated that its procurement lifecycle averaged 16 days.

Process mining revealed a more nuanced picture:

Approximately 40 percent of transactions required 27–30 days.

Approval stages introduced multiple days of inactivity.

Certain teams consistently bypassed standard steps, causing downstream delays.

A subset of suppliers accounted for a large share of manual interventions.

By addressing a single recurring bottleneck, delayed approvals - the company reduced the cycle time by nearly 40 percent and improved supplier performance management practices.

Why Enterprises Still Need Process Mining

Before implementing automation or AI, organizations require a clear understanding of the processes they intend to optimize. Without this insight, automation may simply accelerate mistakes and AI models may depend on unreliable or incomplete workflows.

Process mining addresses these risks by providing:

1. Transparency Into Operational Inefficiencies

It reveals where processes diverge from expectations and where performance losses occur.

2. Early Identification of Risk and Compliance Issues

Deviations from standard procedures become immediately visible.

3. Evidence for Redesigning or Automating Workflows

Organizations can prioritize improvement initiatives based on measured impact rather than intuition.

4. A Reliable Foundation for AI and Advanced Analytics

Accurate, stable processes enhance the performance and trustworthiness of AI systems.

Who Benefits Most From Process Mining?

Process mining is applicable across industries and functions, particularly where routine, high-volume, multi-step workflows exist. Common use cases include:

Procurement / Purchase-to-Pay

Order-to-Cash

Manufacturing operations

Inventory and logistics

Finance and accounting

Customer service and ticket management

Quality assurance

Healthcare patient journeys

Retail operational processes

Any function that relies on structured steps and enterprise systems stands to gain significant value.

How Process Mining Works

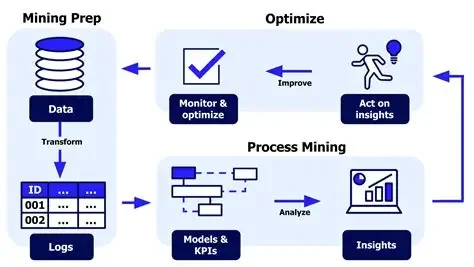

The process typically follows four stages:

1. Select the Target Workflow

Organizations begin by identifying a process with measurable challenges—delays, cost overruns, compliance issues or customer impact.

2. Extract and Prepare Event Log Data

Event logs are collected from the relevant systems and prepared for analysis. Key fields normally include case ID, activity name, timestamp, status and operator.

3. Generate the Actual Process Model

Specialized tools reconstruct the real workflow, often revealing variations and complexities that differ substantially from the documented process.

4. Diagnose Issues and Recommend Improvements

Analytics reveal bottlenecks, rework cycles, long queues, deviations and performance outliers. This analysis forms the basis for operational enhancements, automation or redesign.

Relevance in an AI-First Era

As enterprises accelerate AI adoption, the importance of accurate, efficient and well-governed processes increases significantly.

AI systems rely on clear, consistent workflows; otherwise, they may automate work incorrectly or provide unreliable recommendations.

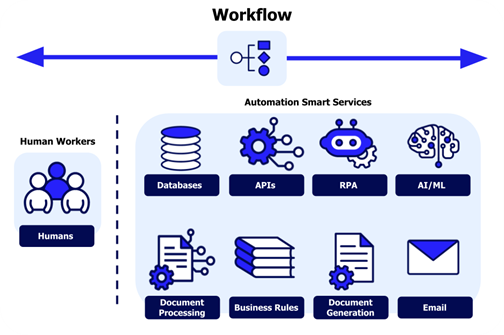

Process mining provides the operational stability required for:

intelligent automation

predictive insights

decision-support systems

autonomous process flows

In other words, AI amplifies performance, but process mining ensures the underlying processes are worth amplifying.

Conclusion

Process mining remains one of the most valuable yet underutilized tools in enterprise transformation. It provides unmatched visibility into real operations, enabling organizations to improve efficiency, strengthen compliance, reduce cycle times and build a reliable foundation for automation and AI initiatives.

As organizations advance toward more intelligent, autonomous operations, process mining is likely to return as a critical capability—one that offers clarity, accuracy and strategic insight in a rapidly evolving digital landscape.